Product

2018

Challenge

Jointspace

How can the manual labor of Japanese joinery be translated into an automated CNC fabrication?

Outcome

Additional

Details

JointSpace, creates a series of modular joint constructions that can be aggregated at different levels of scale to create a function dictated by the user. Inspired by Sol Lewitt’s prouns, these modular joints are art at an individual level, and turn functional when combined together.

Completed with Eric Duong and Ryan Shih (1 month)

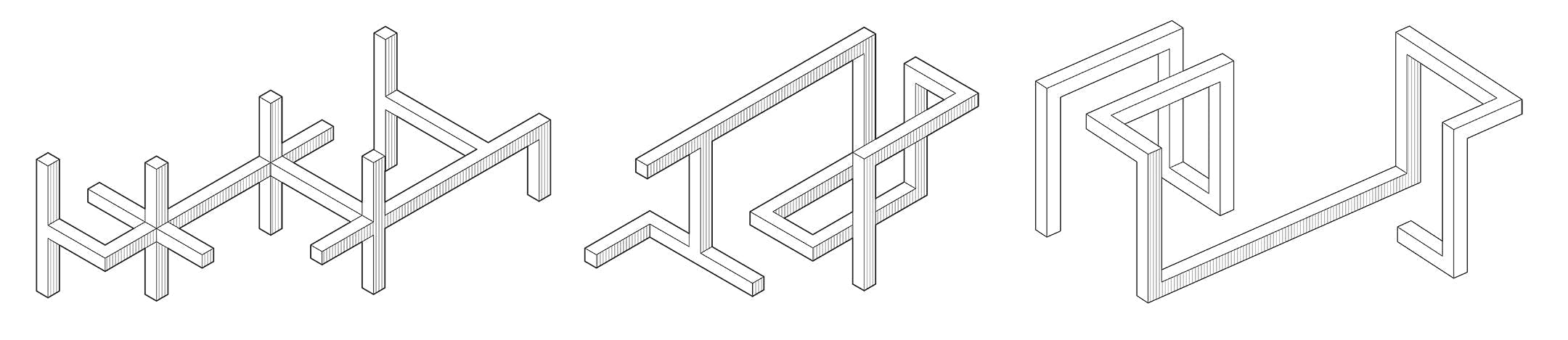

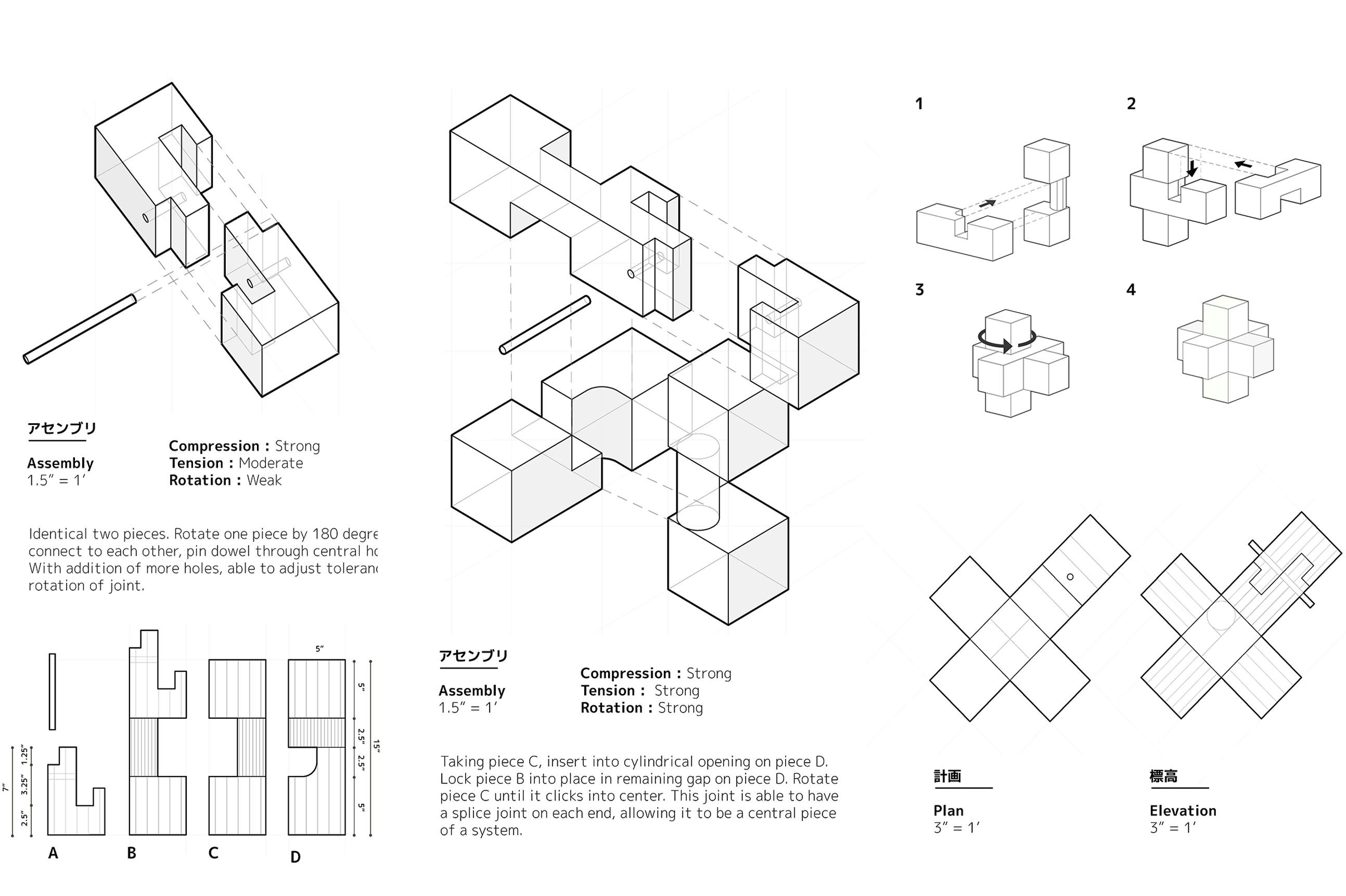

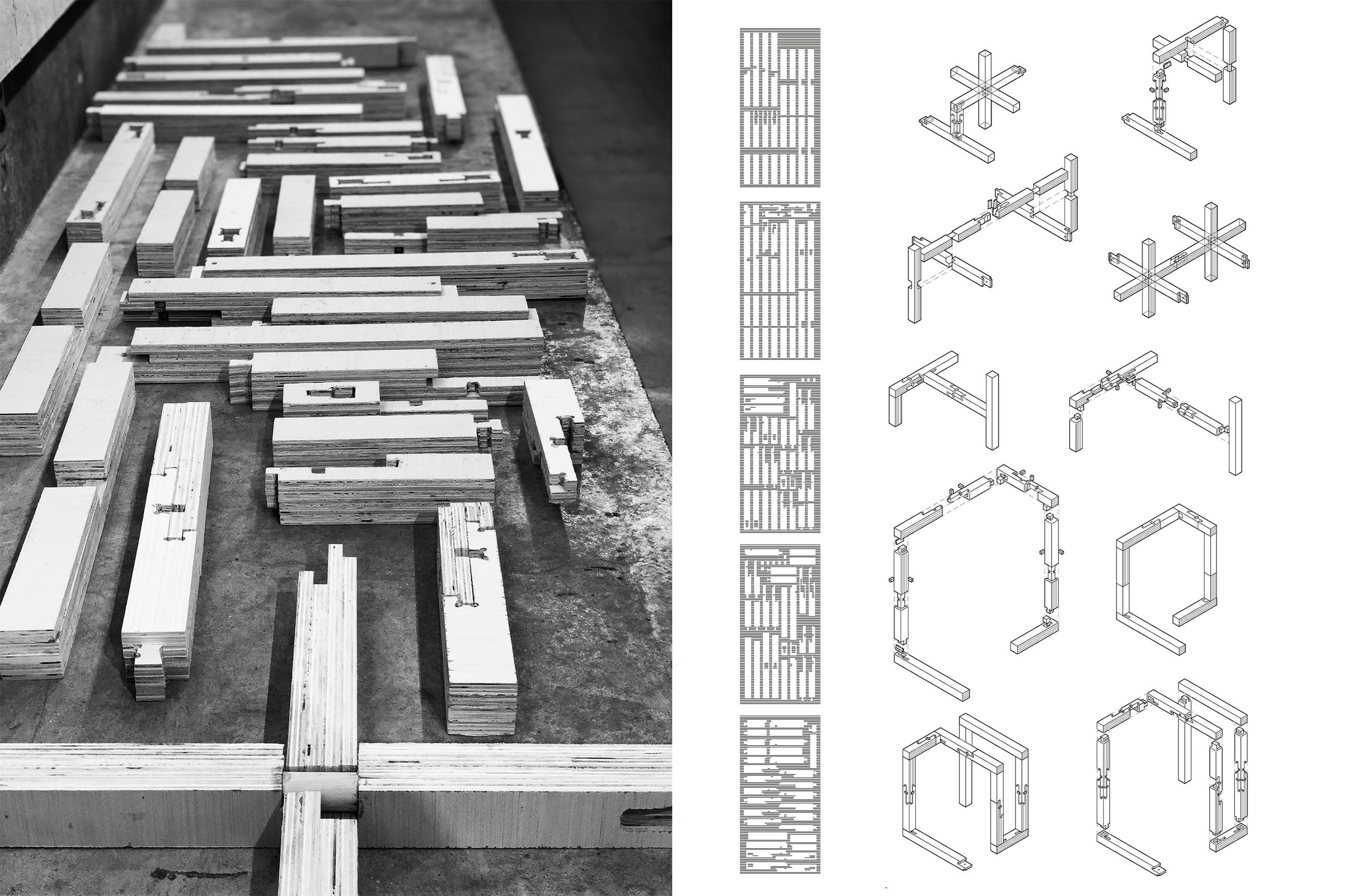

A translation of traditional Japanese woodworking joints into a standardized CNC routed fabrication process. The study began with individual research into existing joints - specifically how they work and within what situations they are commonly used. Following initial research, these joints were combined and adapted to suit an assembly process that required them to be cut in layers. Further studies into modifying these joints included considerations of ways to change them for different uses, such as creating a corner. Jointspace was developed as an exploration of modular units that could be activated at different scales. Based on six traditional Japanese joints, the translated joints are made so that they could be aggregated to discrete infinity, while still maintaining a unique individual character.

Using a CNC Techno Router, each proun was constructed and put together, ready for modulation.